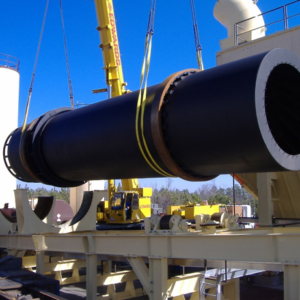

With over 30 years of building and upgrading rotary drying plants, we know your challenges and problems. We can help you better understand your drying process to increase throughput, dry more efficiently, and reduce downtime.

If you want to overcome high moisture in your material, want to lower your cost per ton, are interested in burning an alternate fuel, or simply want to ensure your process is efficient—we can help. Our engineers have rotary drying experience in many different materials, including: