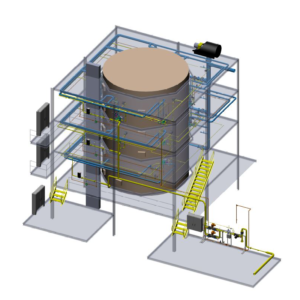

Thermal Solutions specializes in engineering and producing complete combustion systems. These standalone systems provide a “plug and play” experience for our customers. They have a wide variety of uses tailored to our customers’ applications.

Combustion systems are an integral part of the production process. They can be used to warm product to a critical temperature while heavier machinery is prepared for production. Customers looking for a complete combustion system can be manufacturing facilities with integral stages to their process, or an OEM that can sell a combustion system tailored for use with their product. Complete combustion systems include the perfectly sized burner for your application, fuel inlet connection, and all the safeties in between. Push the start button and instantly enjoy increased efficiency.